Liquid Crystal Technologies

In contrast to normal liquids where the atoms and molecules do not show any ordered structure at all, the usually rod-shaped molecules in liquid crystals show some remnant of a structure and order above the melting point of the material, resulting in anisotropic properties. Many of these material are birefringent. If such materials can be oriented in an external electric field, they can be used in liquid crystal displays (LCDs). Most currently deployed display effects are based on the change of the polarization of light as passes through a birefringent material. The liquid crystal cell is inserted between two crossed polarization filters. Light entering the cell after passing the first filter can only pass the second filter if the direction of (linear) polarization is shifted in the birefringent liquid crystal layer.

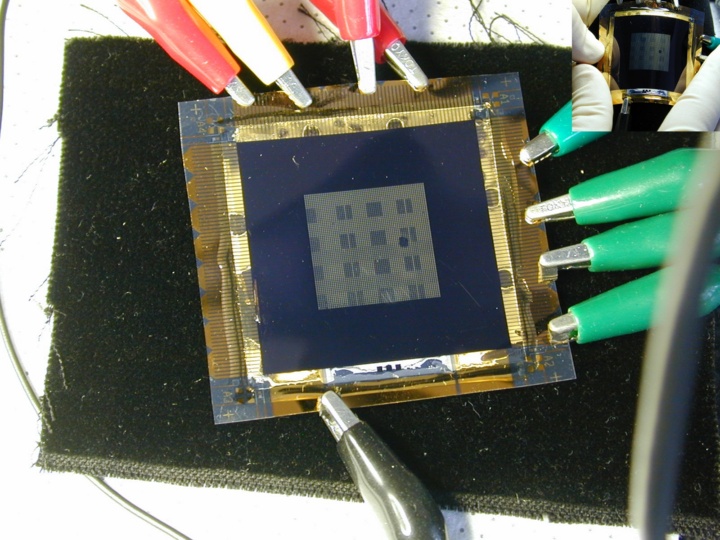

LCDs have been dominating the display market ever since they started replacing the cathode ray tube. The IGM and its predecessors have over 30 years of experience in developing and implementing liquid crystal cells on glass and plastic foil substrates. The main challenges are the determination and application of the best building and filling processes as well as the creation of orientation layers suited to desired symmetries of the liquid crystal and the precise thickness of the cell across the large area of a display.

The IGM offers extensive expertise in the processing of numerous different liquid crystal effects and the relevant processing technologies:

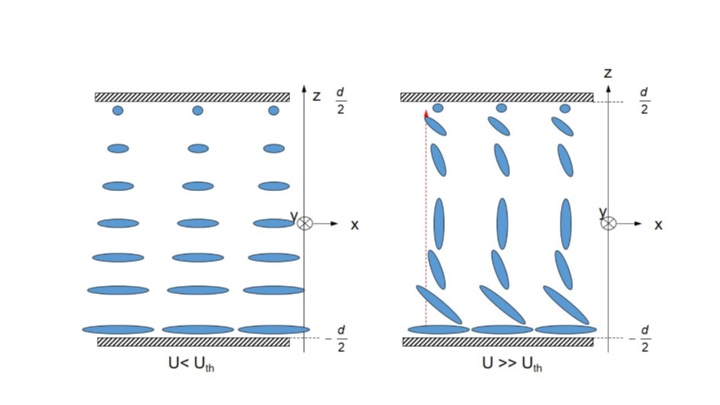

Due to the orientation layers applied to the inside of the top and bottom glass subtrates, the liquid crystal layer in a twisted-nematic cell shows a helical structure with a 90º twist across the thickness of the cell. Light that has been linear polarized in parallel to the orientation of the liquid crystal follow this twist as it passes through the liquid crystal layer and will pass the crossed second polarizer unhindered (white).

If an electric field is applied the liquid crystal will orient itselves along the direction of the field. The light is not propagating along the long axis of the crystals and does not experience birefringence. The direction of polarization remains unchanged and the light cannot pass through the second filter.

The IGM can process and implement TN-cells in various configurations.

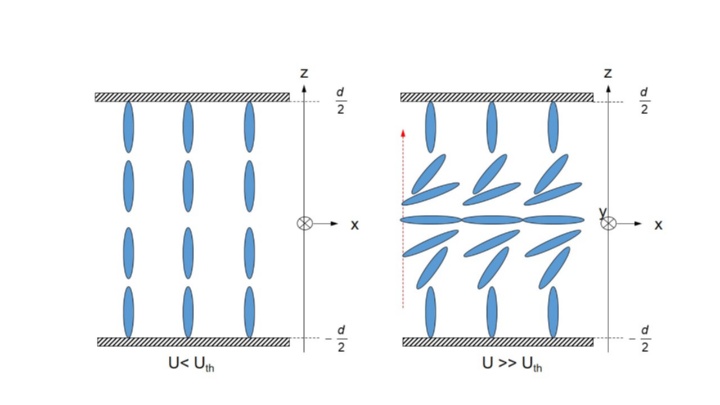

The rod-shaped liquid crystal molecules in a vertically-aligned cell are aligned vertically to the surface of the substrate using a suitable orientation layer. Linear polarized light passing through the cell does not experience birefringence and will therefore not pass the second, crossed polarizer (black).

Applying an electric field will orient the liquid crystals perpendicularly to the field. Light will now experience bifringence and optimizing the thickness of the cell accordingly can have its direction of polarization turned by 90º. It will now pass the second polarizer (white).

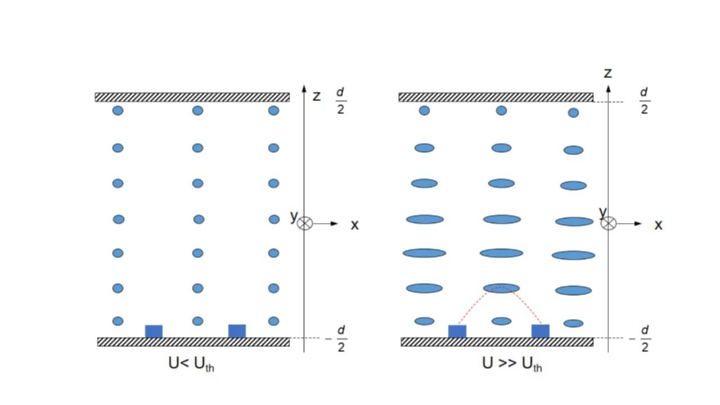

In an in-plane-switching cell the liquid crystal is oriented in parallel to the surface of the substrate. Light linear polarized in parallel to the orientation of the crystal will pass through unchanged and will not be able to pass the crossed second polarizer (black).

Applying a voltage to a series of parallel conductors on just one of the substrates will reorient the crystal in the direction of the field, turning it in the plane parallel to the substrate. Light passing through the cell will experience some birefringence and the corresponding change in polarization. Some of the light will be able to pass the second, crossed polarizer (white).

The maximum transmission of an IPS cell is generally inferior to that of a TN or VA cell but the perceived brightness is a lot less dependent on the viewing angle and the cell is easier to implement than other angle independent technologies.

If droplets of liquid crystal are finely dispersed and randomly oriented within a polymer matrix they will appear opaque (Polymer Dispersed Liquid Crystal, PDLC). Applying an electric field reorients the crystal. Carefully choosing the liquid crystal and polymer can create a configuration where light passing through perpendicularly does not experience birefringence and the layer will appear clear and transparent. This effect can be used in Displays of in smart glas (privacy glas).

Ferroelectric liquid crystals (FLC) posses an inherent dipol moment that allows for very fast switching. Optimized control allows for bistabil states that are retained almost indefinitely even if the switching voltage is turned off.

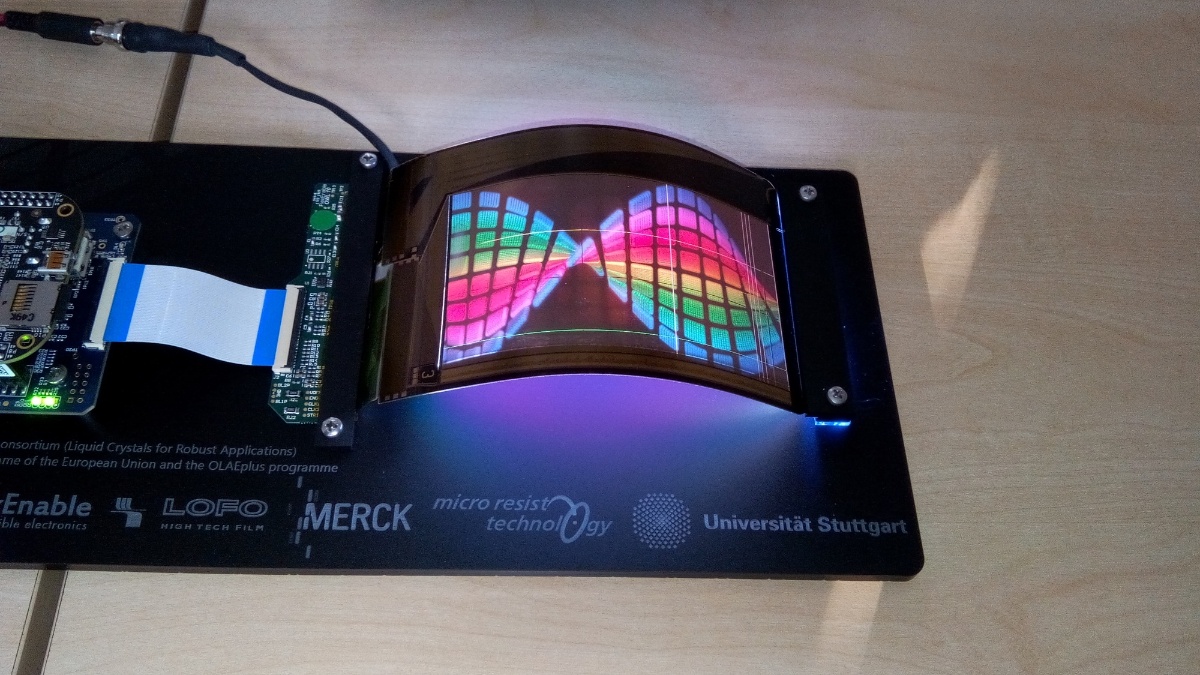

OLED

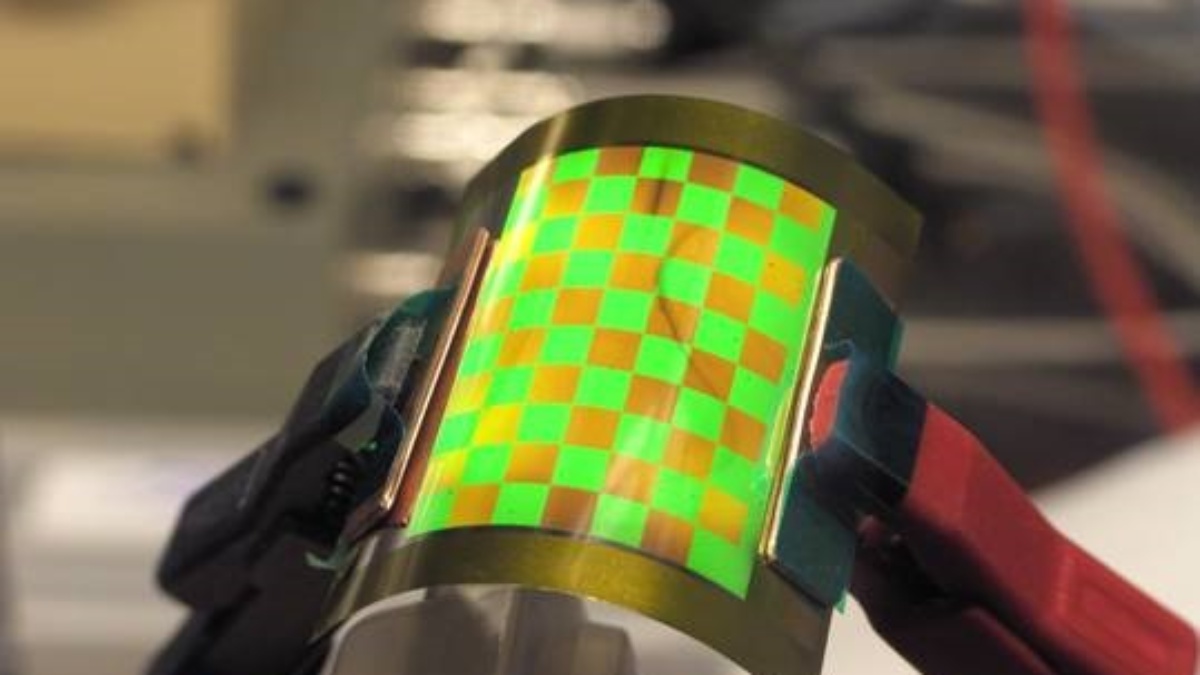

Organic Light Emitting Diodes (OLEDs) allow for the implementation of self-luminous displays that can be very thin as they do not require a liquid crystal cell. The IGM is mostly focused on the design of less complex but high quality TFT backplanes for active matrix oleds (AMOLEDs). It does however have the capability of processing both small molecule and polymer OLED emitters in both white or color.

The IGM also designed polarized light emitting OLEDs by orienting the molecules of the organic semiconductor or by inserting special photonic materials into the OLED stack.

Other Display Effects

In addition to the above mentioned, market dominating technologies, the IGM is also investigating further display effects. Electrophoretic displays (e-Paper) utilize the movement of electrically charged dye particles in an electric field. Such displays are used in e-book readers or simple displays like prices in supermarkets and take advantage of the display's bistabil nature.

Electrochrom displays utilize materials that change their colors when a current is applied. These displays can also be made bistabil and are used in dimmable car mirrors.

Further Information

Holger Baur

Dipl.-Ing.Deputy Head of Institute, Head of department

Patrick Schalberger

Dr.-Ing.Deputy Head of Institute, Head of Laboratory